Streamlining Care Delivery with NeoFlow® to Improve Efficiencies in the Neonatal Unit

- Published on:

Streamlining Care Delivery with NeoFlow® to Improve Efficiencies in the Neonatal Unit

- Published on:

On this page

What does efficiency mean in healthcare?

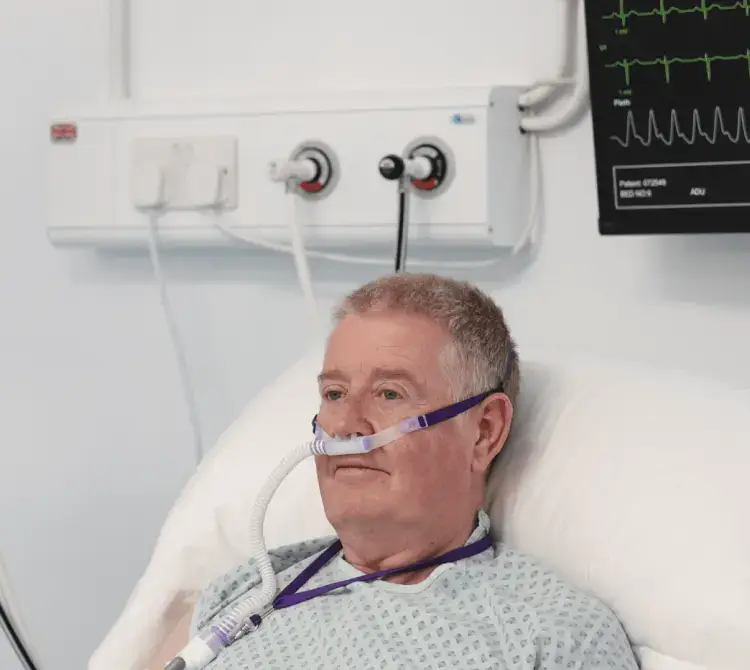

Efficiency in healthcare means delivering high-quality care and improving patient outcomes while minimising waste and reducing costs [1].

It sounds logical and should be easy, right?

Healthcare costs are rising every year; at an expected 2.8% a year for the next three years [3] and yet providers are being asked to cut expenses without sacrificing care quality. Advances in medical technologies and materials means an ever-evolving catalogue of products with increasing complexities and costs.

The NHS’s new 10-year plan prioritises value-based care focusing on better outcomes with the money we spend. It sets high goals and expectations that the NHS will be in a surplus balance by 2030. Achieving this requires effective planning and better use of resources to maximise taxpayer value [2]. Meaning, we must get the basics right.

But like so many others, we faced rising costs, increasing product complexity, and ongoing pressure to cut spending while still delivering the best care. When our high-flow prongs were suddenly discontinued, it really brought these challenges to the forefront. We couldn’t safely deliver high-flow therapy, and we had no alternative on hand.

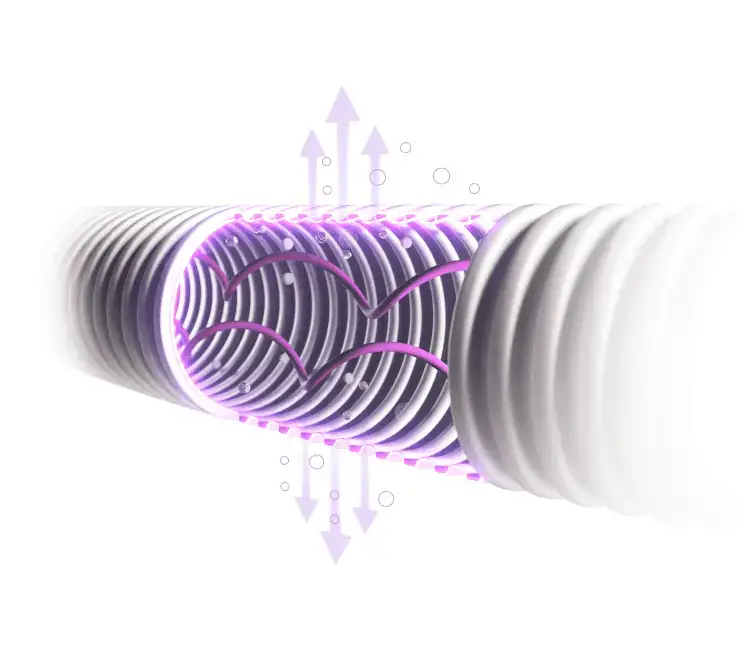

That’s when we reached out to multiple suppliers—and Eakin Healthcare were the ones who stepped up. They quickly recommended an effective replacement from the NeoFlow® range, and in doing so, helped us completely re-evaluate how we were working.

When reviewing our respiratory consumables, we discovered that we had 49 respiratory consumables for two types of ventilators. we realised there must be a better solution, so we set about looking for alternatives.

Eakin Healthcare provided a solution that helped us streamline and improve efficiency:

Waste

We found four products we didn’t even need, and staff were regularly opening full sets, only to throw parts away. That waste wasn’t just physical—it was financial.

Switching to NeoFlow® made a huge difference. Each CPAP generator includes three prong sizes, individually packaged. Now, we only use what we need, and the rest goes back in the cupboard, not in the bin. That change alone is projected to save us around £7,000 a year—simply by reducing unnecessary waste.

Space

By standardising our respiratory supplies, we reduced the number of consumable items from 49 to 23. That freed up a significant amount of cupboard space. Reorganising the system helps staff work more efficiently, allowing them more time with patients and families.

Cost

By streamlining our ventilator setup process and introducing the NeoFlow® range, we estimate a significant annual saving of about £19,000 – funds that can be reinvested in patient care, new initiatives, or future needs.

Instead of ordering parts individually – we now have one complete system that meets our needs. Each CPAP generator comes with three sizes of prongs individually packed; the ones they don’t need now go back in the cupboard instead of the bin, not only is it more cost-effective, but it’s also more consistent and much easier to manage.

Training

We created new training protocols, ensuring that all team members were familiar with the streamlined process and understood the rationale behind each step. This not only reduced confusion but also empowered staff to question existing practices and suggest further improvements. Our collaborative approach fostered a sense of ownership and pride in creating a better working environment.

The feedback from the team was extremely positive – staff reported feeling less overwhelmed by choice, and new starters found it much easier to learn the ropes. Ongoing monitoring and evaluation meant that if any issues arose, they could be quickly addressed, allowing continual refinement of our system.

Supply chain optimisation

One benefit with working directly with Eakin Healthcare, the supplier was how they helped us make sense of an increasing complex respiratory market. The team gave us the knowledge and support to make informed decisions.

Optimising supply chain management is essential for minimising waste and guaranteeing timely access to critical resources. This approach results in reduced inventory levels, fewer orders, decreased lead times, lower waste output, and more efficient use of space.

Sustainability

All of these changes—cutting waste, improving training, reducing orders—have made our unit more sustainable which is important for planning ahead.

Now let me ask you; When was the last time you thoroughly checked the contents of your cupboards?

Beth Goodwin

Lead Clinical Educator

Worcestershire Royal Hospital, Neonatal Unit

References

[1] The Health Foundation (2022) Improving efficiency in the NHS. Available from

https://www.health.org.uk/features-and-opinion/features/improving-efficiency-in-the-nhs [Accessed 10th July 2025]

[2] NHS (2025) Fit for the Future: The 10 Year Health Plan for England. Available from 10 Year Health Plan for England: fit for the future – GOV.UK [Accessed 10th July 2025]

[3] Woolnough S (2025) The King’s Fund responds to the Comprehensive Spending Review. Available from https://www.kingsfund.org.uk/insight-and-analysis/press-releases/response-comprehensive-spending-review-2025.html [Accessed 10th July 2025]